Bespoke Wooden Floors

If you’re thinking of having a new wooden floor laid in your home or office, your heart may be set on a particular colour or design which you have never seen or found anywhere else. If so, you’re in luck as it’s now possible to create a variety of colours or surface effects to produce some amazing results.

Although a huge array of different woods may be used for flooring such as Walnut or Maple or the more exotic Teak, Marabou or Wenge, Oak is the best hardwood floor with which to create bespoke designs. There are several treatments which can be applied to the wooden boards which help to optimise its natural character and provide the variety of appearances you may be looking for.

Using industrial sized brushes, the softer grain can be removed from an oak board’s surface leaving a more natural texture. Its durability is increased as this brushing process helps the wood to absorb more oil. The application of natural oils in different colours provides a uniqueness and as the oils penetrate the wood all the way through keeping it well protected against the wearing from high footfall and offers stain resistance. It also means it’s easy to re-oil any area that may eventually look worn.

Black Oiled Oak – Project by Dyfed Richards

Nowadays with the disappearance of old factories or barns, reclaimed timber boards are becoming more scarce. However, the antique look is still in demand. Therefore, machine or hand distressed boards are the solution to sustainable sourcing. With unfilled knots, areas of softer grain scraped away to give undulation and even structurally sound cracks and holes, its appearance can be made to look as if it’s been around for decades.

To give the wood a rich dark colour the boards can be carbonised. It’s like a fuming process without the ammonia. The top layer of the wood shrinks and any moisture content is removed. Steam is then introduced to allow the top layer to adjust to its natural state and allow it to be adhered to the base layer.

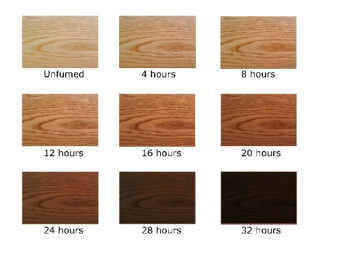

Depending on the depth of colour required, the wood can undergo a fuming process for anything from a few hours to several days. The oak boards are placed in a kiln with spacers between them so the ammonia saturated air can circulate freely around them. Boards that have undertaken this process will not be prone to scratches as the colour will be the same all the way through and they will be less obvious. However, there will inevitably be colour variation due to its nature but this just adds to the natural beauty of the floor.

Image courtesy of en.wikipedia.org